Located in the middle of the forest, 5 kilometres from the Sochaux factories, the Belchamp Technical Centre is one of the PSA Group's main development and experimentation sites.

Established since 1969 in the Montbéliard region, the birthplace of the Lion brand, the Sochaux-Belchamp Technical Centre is one of the four French centres for automotive research and development of the PSA Peugeot Citroën Group. It joins those of La Garenne-Colombes (Centre Technique d'Études de Recherches et d'Essais founded in 1947), Vélizy created in 1966 and Carrièressous-Poissy dating from 1970.

Like most car manufacturers, Peugeot has had its own test department since the late 1960s to develop prototypes of its future vehicles and improve them when they are already in production. Its main technical centre is located in the Doubs region, just a few kilometres from the Peugeot factories in Sochaux, more precisely at the Belchamp site which straddles the communes of Voujeaucourt and Valentigney, to the south of the Montbéliard conurbation. Valentigney is the cradle of the history of the automobile, where the Peugeots, initially craftsmen, then industrialists, settled in the middle of the 18th century.

The test track includes a raised or "banking" ring, similar to that of the Montlhéry circuit and essential for high-speed testing.

© IXO Collections SAS - Tous droits réservés. Crédits photo © Peugeot

A vast and discreet site

A pioneer in the car industry, Peugeot was also one of the first manufacturers in the world to have a private test track. The role of this track is to test a prototype car to the maximum, sometimes to the point of destruction, in order to ensure the optimal construction of the mass-produced model. To do this, the most difficult conditions that a vehicle will face in daily use must be recreated. All these developments must also be carried out discreetly in order to keep certain manufacturing techniques confidential. This is why Peugeot's Belchamp technical complex is located in the middle of the woods, out of sight, just like the other PSA Group test sites at La Ferté-Vidamme in the Eure-et-Loir since 1938 (Citroën) and at Mortefontaine in the Oise; a site owned by Peugeot until 1988. The Belchamp Technical Centre covers 450 hectares and includes a total of 36 kilometres of test tracks. Up to 1,200 employees work there on a permanent basis and each year the cars designed by Peugeot and Citroën travel an average of 11 million kilometres, i.e. 275 times around the Earth!

For hundreds of hours and over thousands of kilometres, the PSA Group's cars are put to the test on the various tracks at the Belchamp site.

© IXO Collections SAS - Tous droits réservés. Crédits photo © Peugeot

The realities of traffic

To carry out test drives in a variety of conditions, there are three main facilities on the site. The first circuit, known as the "dry track", is 2.16 km long and is paved with asphalt similar to that used on the majority of the road network. However, in some of its bends, glass plates have been placed to recreate the difficult conditions of an icy road. A second circuit, developed over 1.88 km and known as the "wet track", has a low-grip surface and is constantly watered to maintain a layer of water of one millimetre. This is to recreate the most difficult traffic conditions and to study the behaviour of a vehicle that is a victim of aquaplaning, for example. Finally, a track called 'Synthesis and Behaviour' was created to develop everything relating to the active safety of a vehicle, such as the first ABS assisted braking systems and more recently the ESP (Electronic Stability Programme) or the ASR (Anti-Skidding System).

This aerial view shows the endurance track (left) in Voujeaucourt and the speed ring (right) in Valentigney, with the Doubs in the foreground and Montbéliard in the distance.

© IXO Collections SAS - Tous droits réservés. Crédits photo © Peugeot

A tough test

City traffic is particularly hard on the mechanics, and a "city" circuit was put into operation early on with a 7.3 kilometre reconstructed network of speed limit signs, red lights and stop signs. There are also two roundabouts and car parks for manoeuvring, as well as 15 cm high pavements on which the wheels and tyres will deteriorate as in reality... To complete the development of a new model, it will undergo an accelerated corrosion test during which it will be driven for thousands of kilometres on gravel tracks, crossed fords in muddy and salty water, and kept in hot and humid rooms for hundreds of hours... Its suspensions will also be abused on a chassis dynamometer, while the noise and vibrations generated by its mechanics are meticulously analysed in an anechoic chamber, or deaf chamber, with neutral acoustic conditions, in order to improve sound comfort in the passenger compartment.

The Belchamp Centre is constantly adapting to new environmental and safety requirements in order to keep PSA at the highest level in the face of competition.

© IXO Collections SAS - Tous droits réservés. Crédits photo © Peugeot

Crash tests

Among the many facilities at the Belchamp Centre is a crash test area with three experimental zones. The first is a crash wall that simulates the impact of a vehicle against a fixed obstacle. The wall and the vehicle are equipped with numerous instruments that can measure all the forces at the time of impact. It is completed by a device for analysing the impact of a carriage launched at full speed against a stationary vehicle. The third piece of equipment is designed to study the damage caused to passengers during a frontal impact, using dummies equipped with around 100 sensors. The Belchamp Centre carries out up to 400 crash tests per year for all the group's brands.

Tyres put to the test

In order to determine the optimum choice of a type of tyre for a new Peugeot model, the Belchamp Technical Centre has three specific test benches which were initially installed at the La Garenne-Colombes site. These machines are responsible for testing the structural resistance of the tyre to significant load transfers during acceleration and braking, in bends, as well as its deformation due to bumps and holes in the surface. A tyre is tested for two days on a rolling resistance test bench (BRR), a static stiffness test bench (BRS) and a machine called Flat-Trac for measuring vibration absorption.

Recent articles

24/06/2025

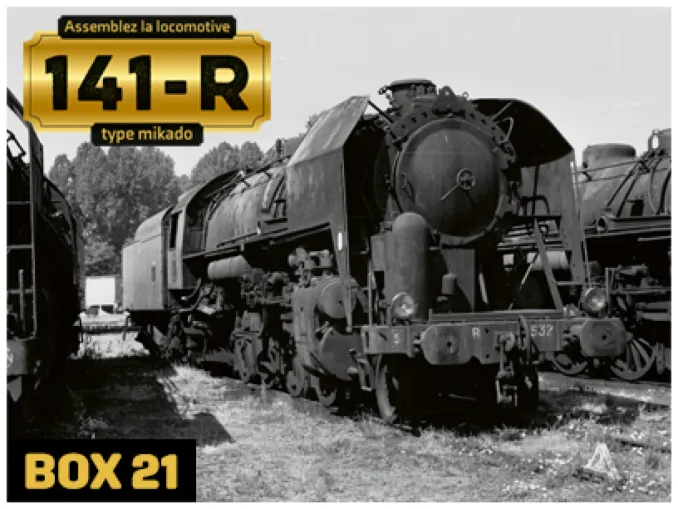

The 141-R, late queens of petrol

With the 141-R, the reign of coal in France suddenly declined.

Read more

24/06/2025

The 141-R, the arrival of the second tranche

The 141-R-701 to 1340 locomotives make up the second tranche, delivered from 15 August 1946, while those in the first tranche are still being delivered.

Read more

24/06/2025

THE 141-R CHANGED THE ROLE OF STAFF

These powerful, robust locomotives, imported from the United States after the Second World War, radically transformed the role of the staff at SNCF depots in terms of rail transport in France.

Read more

English

English français

français Deutsch

Deutsch español

español italiano

italiano português

português